The HydroFLOW™ Water Conditioner: an easily installed, eco-friendly device that inhibits the formation of scale, all without costly treatment programs.

Based on over twenty-five years of experience, the patented HydroFLOW technology works with all equipment and piping systems, including:

- Cooling towers

- Boilers

- Heat Exchangers

- Water and Wastewater Piping

- commercial pools

- Wells: water, injection, oil and gas

- Pumps

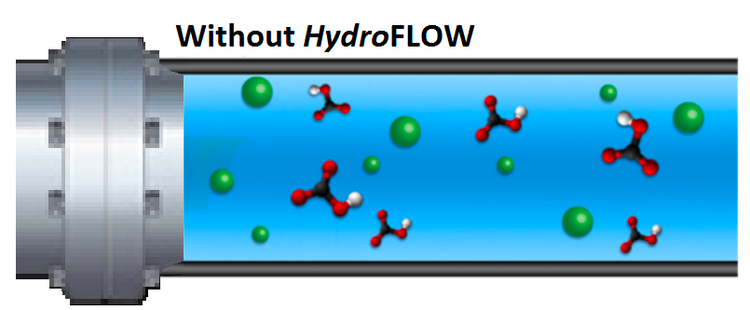

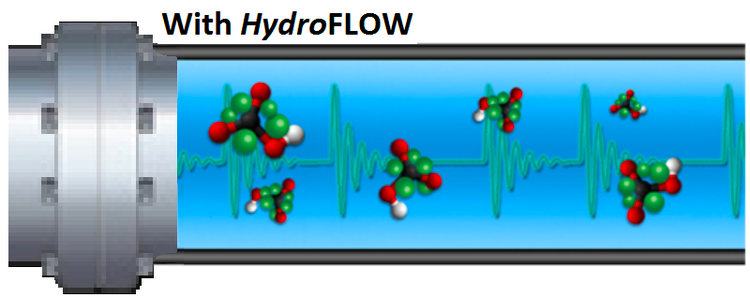

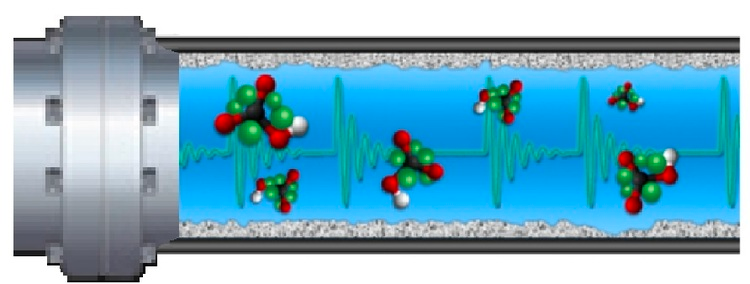

Installed on the exterior of any piping system or pipe material, the HydroFLOW™ device employs a ferrite ring to induce an oscillating 150 kHz frequency that penetrates the pipe wall and travels both upstream and downstream from the point of installation. The water within the piping system, acts as a conduit to propagate the signal throughout the system, conditioning the water, whether it is moving or stationary. Testing has proven that the HydroFLOW™ signal is more efficient and effective than similar water conditioning technologies.

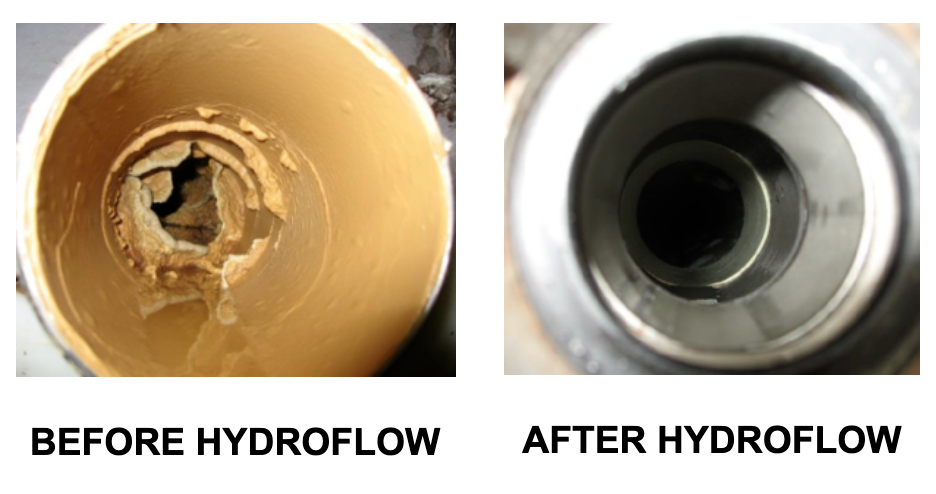

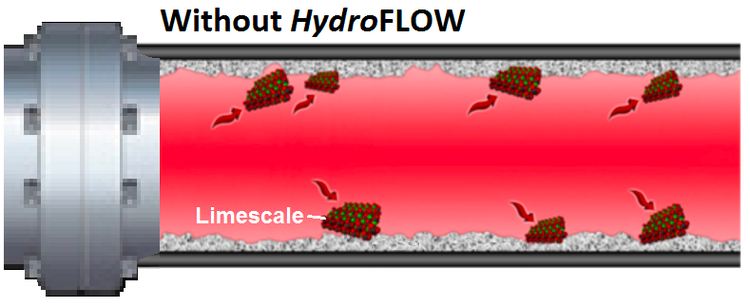

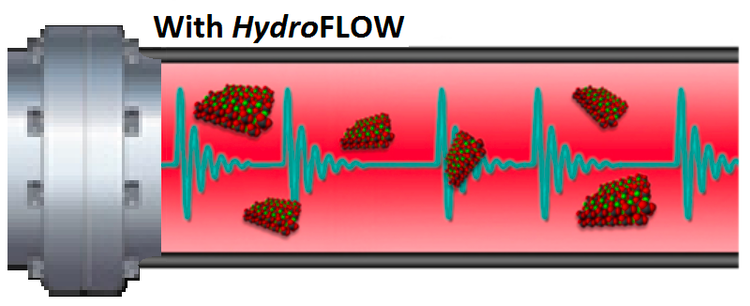

The HydroFLOW™ signal induces the dissolved minerals to cluster and precipitate as stable crystals that remain in suspension and do not adhere to piping and equipment surfaces. The suspended particles are filtered or flushed out with the process blowdown. Existing scale is re-mineralized, softening over time, and erodes away leaving a clean surface that is free of scale.

HydroFLOW units are available to fit pipe sizes ranging from 1.5” to 72” outside diameter.

Contact Us to Schedule a Risk-Free Evaluation, or

to Learn More about HydroFLOW for scale control and removal.

Download Lab Reports and Case studies on Scale Control on our Resources Page

Common scale problems with HydroFLOW™ solutions:

- Source water high In Calcium hardness. Hard source water requires greater volumes of make-up water to dilute the concentrated minerals that build-up in cooling water recirculating water. Dilution of the water helps to prevent internal surfaces of the tower, fill, and chiller m scaling, but it results in additional water charges.

- High Blowdown discharges to the municipal sewer: To prevent scaling of tower internal surfaces and chiller tubes, circulating water from the cooling system must be continuous discharged or blown down to the sewer. Not only are charges incurred for the purchase of the water, but sewer costs are often higher.

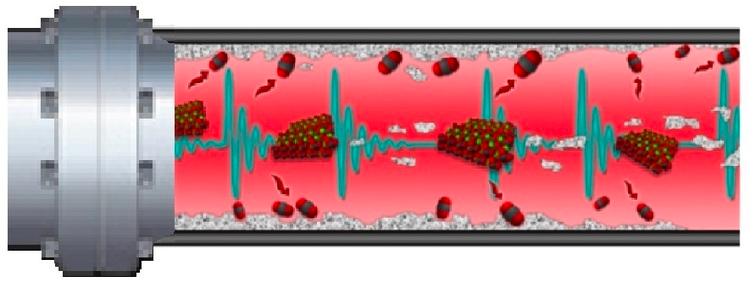

- Scaling of the chiller tubes and fill: Attempting to reduce water consumption, often leads to over concentration of the dissolved minerals in the recirculating water, causing it to precipitate and to adhere to the internal surfaces of the system as a hard concreate-like coating.

- Loss of heat transfer efficiency: The coating or scale acts as insulation, lowering the heat transfer efficiency of the chiller tubes.

Minerals are dissolved in solution as TDS (Total Dissolved Solids) .

When the Hydropath signal is present, dissolved minerals combine together to form loosely held clusters. The clusters develop into seed crystals that do not form as hard scale

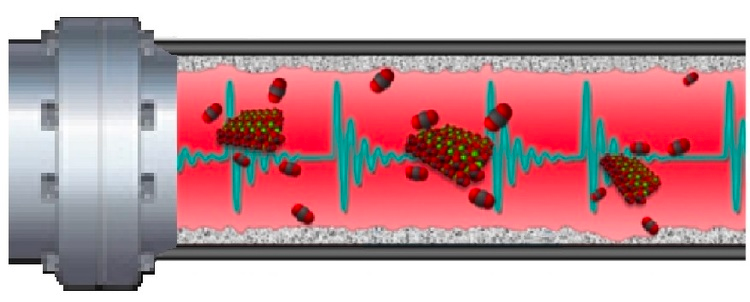

When temperature or pressure change occurs, minerals precipitate out of solutions and accumulate as hard scale in pipes, holding tanks, pumps and on heating elements

When the clusters precipitate out of solution, they form stable “soft scale” crystals that do not accumulate as hard scale. Over time the hard scale is softened by the Hydropath signal which is gradually released as soft scale. No new Hard Scale is able to form

Prevention of Limescale

When the Hydropath signal is present, dissolved minerals combine together to form loosely held clusters.

When the clusters precipitate out of solution, the form stable “soft scale” crystals that do not accumulate as hard scale.

When calcite crystals form, they release carbon dioxide which gradually dissolves exiting lime scale deposits.

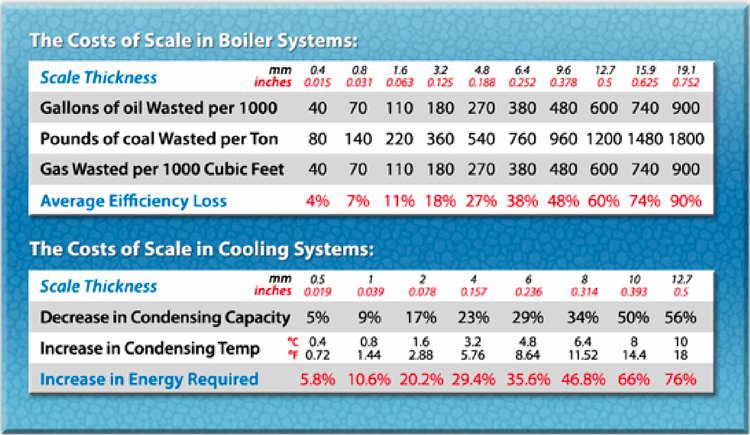

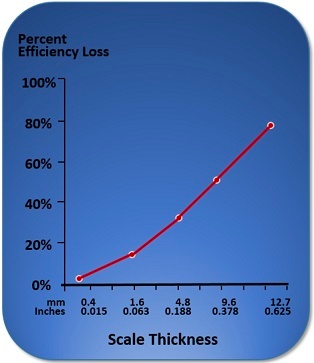

Efficiency Loss Due to Scale